Fluorocarbon (FPM, FKM, Viton®) O-Rings

2025/10/16 15:28:17

No Pics.

Introduction

Fluorocarbon (FPM, FKM, Viton®) O-Rings Material Description:

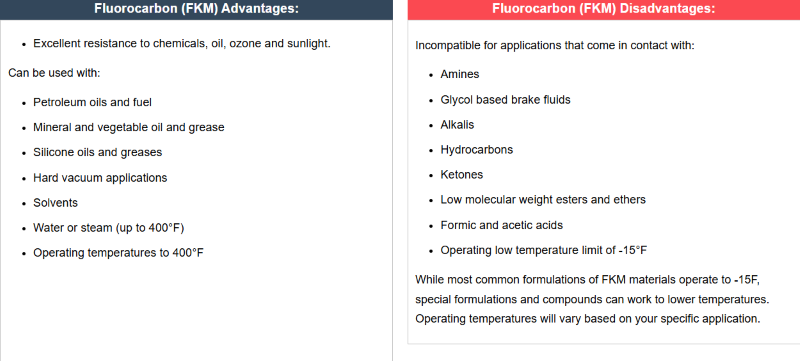

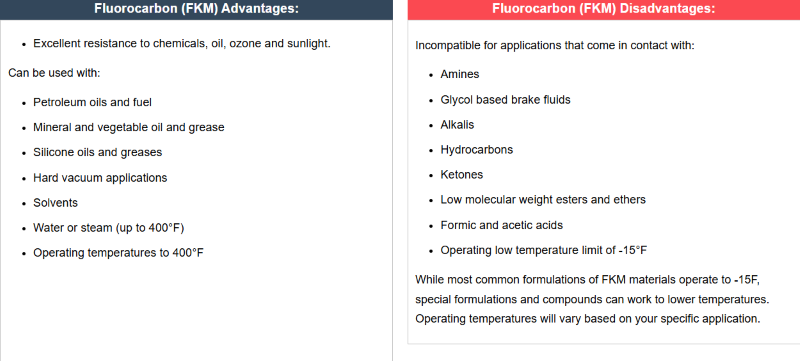

Fluorocarbon (FPM, FKM, Viton®) o-rings offer excellent resistance to chemicals, oil, ozone and sunlight with a higher temperature range than nitrile, AFLAS, EPDM and some of the common industrial materials with an operating range up to 400° F. Can be used in petroleum oils and fuel, non flammable hydraulic fuels, acids, aircraft engine applications, synthetic hydraulic fluids, organic solvents, mineral and vegetable oil and grease, aliphatic hydrocarbons (butane, propane, natural gas), hard vacuum applications, silicone oils and greases, solvents and water or steam (up to 400°F). It cannot be used in amines, glycol based brake fluids, methanol, ammonia gas, amines, alkalis, hydrocarbons, ketones, low molecular weight esters and ethers, fireproof hydraulic fluids, formic and acetic acids.

Also Know As:

Viton®, Dai-el®, Fluorel®, Tecnoflon®

Viton® Material Description

Viton® is a trade name for the Chemours brand of fluorocarbon

Viton® Variations

Viton® variations include Viton® A, Viton® B, Viton® F, Viton® GLT, Viton® GFLT, Viton® Extreme (ETP).

Standard Types of Viton® (A, B, F) are defined by their relative resistance to chemicals due to different levels of fluorine content. Viton® general type A has a 66% composition of fluorine, Viton® middle fluorine content type B has a 67-68.5% composition of fluorine, and the high fluorine content type F has a 70% composition of fluorine. Of these standard types, Viton® F demonstrates the best fluid resistance but reduced flexibility at low temperatures. On the other hand, Viton® A has the best flexibility at low temperatures and comparatively reduced fluid resistance.

Because of this tradeoff between chemical resistance and low-temperature flexibility, Viton® GLT and GFLT were created using copolymerized fluorinated vinyl ether monomer. This allows for Viton® GLT and GFLT to offer excellent chemical resistance while maintaining low-temperature flexibility.

Extreme Viton®, or Viton® ETP, exhibits the same chemical resistance as standard types of Viton® with additional resistance to acids, hydrocarbons, low molecular weight esters, ketones, aldehydes, and highly caustic solutions.

For more detailed information on specific types of Viton®, please download the Viton® Selection Guide.

Fluorocarbon (FPM, FKM, Viton®) o-rings offer excellent resistance to chemicals, oil, ozone and sunlight with a higher temperature range than nitrile, AFLAS, EPDM and some of the common industrial materials with an operating range up to 400° F. Can be used in petroleum oils and fuel, non flammable hydraulic fuels, acids, aircraft engine applications, synthetic hydraulic fluids, organic solvents, mineral and vegetable oil and grease, aliphatic hydrocarbons (butane, propane, natural gas), hard vacuum applications, silicone oils and greases, solvents and water or steam (up to 400°F). It cannot be used in amines, glycol based brake fluids, methanol, ammonia gas, amines, alkalis, hydrocarbons, ketones, low molecular weight esters and ethers, fireproof hydraulic fluids, formic and acetic acids.

Also Know As:

Viton®, Dai-el®, Fluorel®, Tecnoflon®

Viton® Material Description

Viton® is a trade name for the Chemours brand of fluorocarbon

Viton® Variations

Viton® variations include Viton® A, Viton® B, Viton® F, Viton® GLT, Viton® GFLT, Viton® Extreme (ETP).

Standard Types of Viton® (A, B, F) are defined by their relative resistance to chemicals due to different levels of fluorine content. Viton® general type A has a 66% composition of fluorine, Viton® middle fluorine content type B has a 67-68.5% composition of fluorine, and the high fluorine content type F has a 70% composition of fluorine. Of these standard types, Viton® F demonstrates the best fluid resistance but reduced flexibility at low temperatures. On the other hand, Viton® A has the best flexibility at low temperatures and comparatively reduced fluid resistance.

Because of this tradeoff between chemical resistance and low-temperature flexibility, Viton® GLT and GFLT were created using copolymerized fluorinated vinyl ether monomer. This allows for Viton® GLT and GFLT to offer excellent chemical resistance while maintaining low-temperature flexibility.

Extreme Viton®, or Viton® ETP, exhibits the same chemical resistance as standard types of Viton® with additional resistance to acids, hydrocarbons, low molecular weight esters, ketones, aldehydes, and highly caustic solutions.

For more detailed information on specific types of Viton®, please download the Viton® Selection Guide.

More Pics